Scraper boards – Effective Cleaning for Conveyor Belts

A belt scraper is a crucial component for ensuring efficient and trouble-free operation of conveyor belts. When material sticks to the surface of the belt, it not only increases wear but can also lead to costly downtime and unnecessary maintenance. By investing in high-quality scraper blades from Vendig, you get a solution that reduces the risk of these problems and contributes to a stable production flow. With the right scraper, the lifespan of both the belt and surrounding equipment is extended, providing clear benefits both in the short and long term.

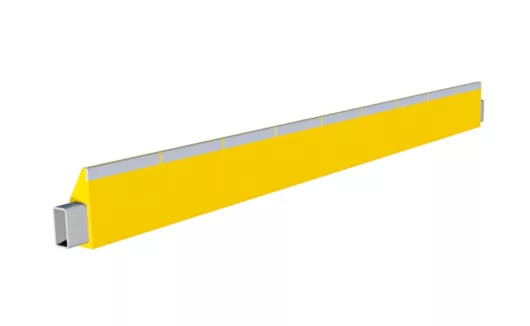

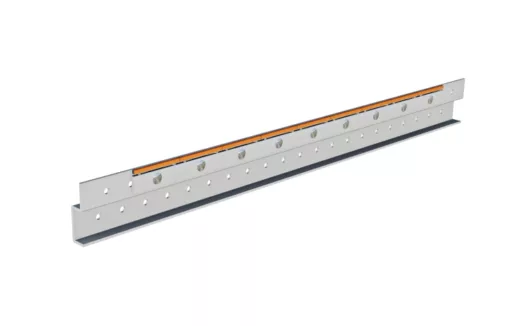

Scraper boards for Effective Cleaning

Belt scrapers, or scraper boards, are designed to remove material residues from the return side of the conveyor belt. This reduces the risk of material buildup on the belt, which can otherwise affect both wear and the working environment in production. By keeping the belt clean, not only is operational reliability improved, but the working environment is also enhanced, as spillage and dust are significantly reduced. At Vendig, we offer scrapers designed to withstand even the most demanding environments on the market – from heavy industry to food production where hygiene is crucial.

Customized Solutions for Different Needs

Since every production has unique conditions, it is important to choose the right type of belt scraper. We offer models in different materials, sizes, and designs that can be tailored to your specific facility. For example, mining and bulk handling require durable scraper board capable of handling coarse materials, while production in the food industry requires materials that are easy to clean and meet high hygiene standards. Our experts are happy to help you develop the optimal solution that meets your specific needs.

Benefits of Using Scrapers

An effective scraper does more than just clean the belt. It contributes to lower maintenance costs, longer conveyor belt lifespan, and more efficient production. By minimizing spillage, you also create a more sustainable operation, both economically and environmentally. A well-chosen scraper can quickly pay for itself through reduced downtime and lower repair costs, making it an important investment for all types of industries. Additionally, a correctly installed belt scraper can improve the lifespan of the conveyor and reduce the need for manual cleaning efforts.

Service and Maintenance of Scrapers

For a scraper to function optimally over a long period, regular inspection and maintenance are required. By repairing the belt and replacing wear parts on time, you can avoid unexpected problems. At Vendig, we not only offer products of the highest quality but also provide advice on how to best take care of your equipment to extend its lifespan. We can also provide tips to optimize settings and minimize unnecessary wear on both the tape and the blade.

Frequently Asked Questions About Scrapers

What type of scraper should I choose?

The choice depends on your production environment and the material being transported. We can help you choose the right scraper for your facility.

How often does a scraper need to be replaced?

It depends on how intensively the conveyor belt is used, but regular inspection and maintenance significantly extend the scraper’s lifespan.

Are Vendigs scrapers suitable for all conveyor belts?

Yes, there are models that can be adapted for most types of conveyor belts and production conditions.